In today’s fast-moving industrial environments, smart operations turn to Modula Vertical Lift Modules (VLMs). They help improve space, speed, accuracy, and safety.

Here’s a breakdown of what businesses stand to gain:

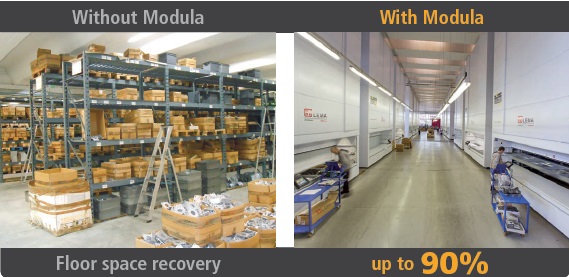

- Up to 90% floor space savings — transform underutilized ceilings into productive storage zones, freeing space for workflow, equipment, or expansion.

- Faster order processing — streamlined picking and replenishment, with high throughput and reduced picking cycles.

- Better inventory accuracy and control — digital tracking, restricted access, and real-time stock updates reduce loss, misplacement, or human error.

- Enhanced safety and reduced operator strain — less physical lifting or reaching means fewer injuries and less fatigue.

- Scalable, future-proof storage infrastructure — modular, customizable systems that grow as your inventory or space needs evolve.

- Suitability for varied industries — from manufacturing and automotive to distribution and e-commerce.

Maximize Your Space Vertically

Traditional shelving and rack systems eat up valuable warehouse space. In contrast, Modula VLMs use your facility’s full vertical envelope. Their lift modules go vertical to 46′3″, recovering up to 90% of floor space compared to conventional shelving.

That kind of space savings is about rethinking your warehouse footprint. It means space freed up for more service bays, expanded production, accessories displays, or other value-added uses.

Modula Vertical Lift Modules deliver stored items directly to the operator, eliminating the time spent walking aisles or searching shelves. Dual-delivery configurations provide the fastest possible picking speed.

With tray throughput rates (up to 140 trays/hour or more as per Modula’s specifications) and payload capacities up to 2,200 lbs., Modula Vertical Lift Modules are designed for high-volume industrial use. As a result, order processing becomes much faster, whether you’re fulfilling repair orders, dispatching parts, or managing spare-parts inventory.

Improve Accuracy, Inventory Control & Security

Modula Vertical Lift Modules bring inventory control into the digital age. With tray-managed access, integrated tracking, and optional WMS (Warehouse Management System) connectivity, you get real-time tracking of parts, lots, or SKUs. This improves accuracy and boosts inventory management when linked to ERP systems.

Modula Vertical Lift Modules bring inventory control into the digital age. With tray-managed access, integrated tracking, and optional WMS (Warehouse Management System) connectivity, you get real-time tracking of parts, lots, or SKUs. This improves accuracy and boosts inventory management when linked to ERP systems.

As the system is enclosed and access-controlled (via touchscreen, login restrictions, or badge entry), businesses dramatically reduce unauthorized access, shrinkage, and damage risk.

Ergonomics is a key benefit of the “goods-to-person” principle behind Modula VLMs. Instead of employees reaching high shelves or bending low to retrieve items, the VLM delivers trays directly to an optimal ergonomic height. This is more than comfort; it’s about long-term sustainability, fewer worker injuries, reduced fatigue, and more consistent productivity.

Flexibility & Scalability for Every Need

One of the most powerful aspects of Modula Vertical Lift Modules is their flexibility. They’re offered in a wide range of widths, heights, and capacities. Each is adapted for industrial products, spare parts, or components, regardless of size or footprint.

Trays can be customized with partitions or dividers, ideal for organizing a wide variety of SKUs, from small parts to bulky items.

Thanks to their modular design, VLM installations can grow with your business. If you expand or relocate, the system can be reconfigured. This allows them to be a long-term investment rather than a one-off solution.

Given today’s labor challenges, space constraints, and demand for fast, accurate fulfillment, Modula Vertical Lift Modules help companies stay competitive. If you’re ready to optimize your warehouse footprint, improve efficiency, and future-proof your operations, a Modula VLM is a strong investment.