High-Density Storage to Save Space & Boost Efficiency

In today’s space-constrained, labor-challenged industrial environments, businesses need smarter storage solutions. Modula Vertical Lifts deliver high-density, automated storage that maximizes vertical space, increases productivity, and improves picking accuracy across manufacturing, distribution, and service operations.

Available in a wide range of widths, heights, and load capacities, Modula Vertical Lift Modules (VLMs) are the ideal storage solution for industrial products, components, and spare parts—no matter the industry or environment.

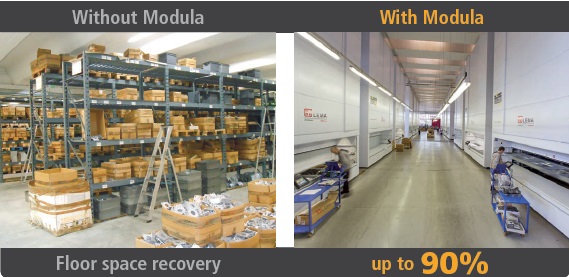

Maximize Vertical Space & Recover Up to 90% of Floor Area

Traditional shelving consumes valuable floor space and limits growth. Modula Vertical Lifts utilize the full floor-to-ceiling height of your facility—storing inventory safely and securely up to 53 feet high.

By going vertical, businesses can recover up to 90% of floor space compared to conventional shelving. This reclaimed space can be repurposed for:

- Additional service bays

- Expanded production areas

- Larger showrooms or offices

- Accessory or parts display areas

Modula’s VLMs enable factories to keep up with their demand by providing a system that takes an operator minutes to learn.

- Recovery of Floor Space – Reduce existing parts storage areas by approximately 85%, while being able to store more parts, add more service bays, have a larger showroom, offices, or an area for accessories sales displays.

- Increased Operator Productivity – Faster processing of sales and service orders.

- Improved Picking & Inventory Accuracy – Achieve inventory accuracy rates up to 99.9% and having improved parts security.

Recover Space

Go vertical to 46'3" and utilize open space

Save Time

Dual delivery for the fastest picking speed

Reduce Injury

Physical and optical safety barriers make it the safest

Security

Operator restrictions can be applied

Accuracy

Managed access tracks inventory in real time

Boost Inventory

Link WMS software to ERP for inventory management

Save up to 35% in Taxes by using Federal Tax Section 179

Ideal Storage Solution to Save Space, Improve Efficiency

Modula Vertical Lifts are designed to grow with your business. Their modular construction allows systems to be expanded, reconfigured, or relocated as inventory profiles and space requirements change—making them a long-term storage investment.

Modula Vertical Lift Modules are widely used in:

- Manufacturing & production

- Automotive & aerospace

- Distribution & logistics

- E-commerce fulfillment

- MRO and spare parts operations

Optimize Your Facility with Modula Vertical Lifts

With rising space costs, labor challenges, and demand for faster fulfillment, Modula Vertical Lifts provide a proven way to reclaim space, improve efficiency, and increase operational accuracy.

If your goal is to modernize your storage, boost throughput, and future-proof your operation, Modula Vertical Lift Modules are the smart, scalable solution.

Faster Picking, Higher Throughput & Improved Productivity

Modula Vertical Lifts operate on the goods-to-person principle, automatically delivering the correct tray to the operator at an optimal ergonomic height. No walking aisles. No searching shelves. The right part is delivered to the right person—every time.

With tray throughput up to 120–140 trays per hour, Modula VLMs dramatically reduce picking times and increase order processing speed for sales, service, and production operations.

Designed for Operator Efficiency

- Intuitive Copilot touchscreen controller

- Barcode scanning for fast, error-free picking

- Minimal training required—operators can be productive in minutes

- Ideal for environments facing labor shortages or high employee turnover

Improve Picking Accuracy, Inventory Control & Security

Modula Vertical Lift Modules deliver inventory accuracy rates of up to 99.9%. With tray-based storage, controlled access, and optional WMS and ERP integration, businesses gain real-time visibility of parts, SKUs, and quantities.

Additional benefits include:

- Reduced mispicks and stock discrepancies

- Improved parts security and access control

- Lower risk of damage, loss, or unauthorized access

The enclosed design and controlled user permissions help protect valuable or sensitive inventory.

Increase Throughput

Operator friendly Modula Vertical Lift module with the touch screen console is suitable for any industrial environment. The ease of use allows the machine to work at high speed with a 120 tray/hour output speed. Tray sizes of up to 13.4 feet wide and load capacities up to 2,208 pounds means that a majority of applications can utilize this high efficiency system.

- Tray widths up to 13.4 feet

- Load capacities up to 2,208 pounds per tray

- Customizable trays with partitions and dividers for optimal organization

With single or dual delivery bays, businesses can design an ergonomic picking station and select the ideal speed for their operation. Dual delivery can reduce tray delivery time by 33% or more.

No Operator? No Problem!

Automated, Operator-Free Picking with Modula OnePick

For operations seeking maximum automation, Modula OnePick offers an advanced, operator-free material handling solution.

Similar to a smart vending system, OnePick:

- Automatically retrieves required items with extreme precision

- Stages inventory for transfer via conveyors, AMRs, or other handling systems

- Integrates seamlessly with Modula’s modular WMS software

OnePick can retrieve multiple rows from a single tray and uses synchronized extractor and tray movements for premium space optimization. The result is a high-efficiency, zero-waste solution ideal for high-volume, high-accuracy environments.

We can help you find the best solution! Call 1-800-466-9561

Robots are on the rise

The utilization of robots has grown tremendously, and new markets are starting to further develop, such as the area of Collaborative Robotics. These modern robots are designed to be user-friendly, so people without knowledge of robotics can operate them. Robot manufacturers such as Yaskawa have made the deployment of these machines easier than you may think.

There are many different models available for different applications to make your business more productive and cost-effective.

Optimize Your Operation

TrackingSystemsIoT solutions are the focal point for managing your organization's assets, personnel, and processes. This is enabled by turnkey tracking and sensor systems that capture data, offering a deep insight into your business's performance and the predictive analytics required for optimized management.