Space Saving Tools, Dies & Molds Storage Solutions that are Safer & Smarter

Modern manufacturing demands precision, uptime, and safe material handling. That’s why advanced tooling, die, and mold storage solutions have become essential for operations looking to increase efficiency, optimize space, and streamline access to heavy or uniquely shaped equipment.

Vertical lift modules (VLMs) and automated storage systems elevate storage efficiency by moving inventory upward instead of outward, allowing facilities to reclaim valuable floor space while doubling or even tripling storage density.

With load capacities ranging from 2,000 to 10,000 pounds per shelf, these systems securely support even the heaviest dies and largest molds in a compact, easy-to-navigate layout. Modular designs adapt easily as tool sizes and storage needs evolve, ensuring lasting flexibility.

The benefits of modern tooling, die, and mold storage solutions include a powerful combination of safety, space optimization, and workflow efficiency—making them a strategic investment for any manufacturer looking to elevate productivity and protect valuable equipment.

Space Saving

Vertical shelving reduces footprint

Safety

Forklift-free, less handling

Flexibility

Fixed or adjustable shelving

Modular Design

Adaptable to different tool sizes

Heavy Duty

Up to 10,000 pounds per shelf

Efficient

Quicker retrieval, better management

Ask us how to SAVE up to 35% in Taxes with Section 179

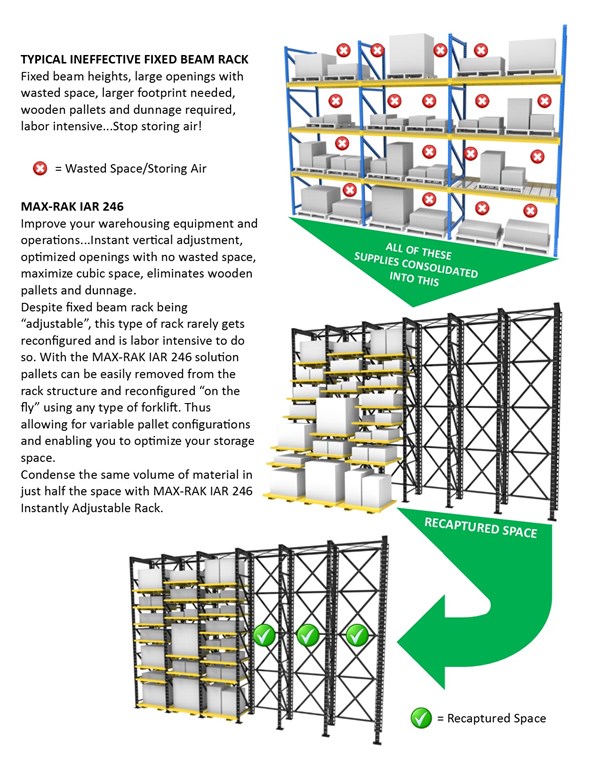

Space Saving Advantage

High-density tooling, die, and mold storage systems reclaim valuable floor space by moving storage vertically. Instead of spreading equipment across floor-level racks, vertical racking leverages unused ceiling height. Whether storing large dies or oversized molds, these vertical solutions create a compact, organized, and highly accessible layout.

High Density-Efficient

Modular-Reconfigurable

Flexible Configurations

Maximum Cubic Capacity

Optimize Picking Layout & Operations

Eliminate Wasted Space

Improve Efficiency

Increase Accuracy

Asset Protection

Immediate Access

We can help you find the best solution! Call 1-800-466-9561

More Efficient & Safer Solutions

Small, Medium and Large Tool, Die and Mold Storage

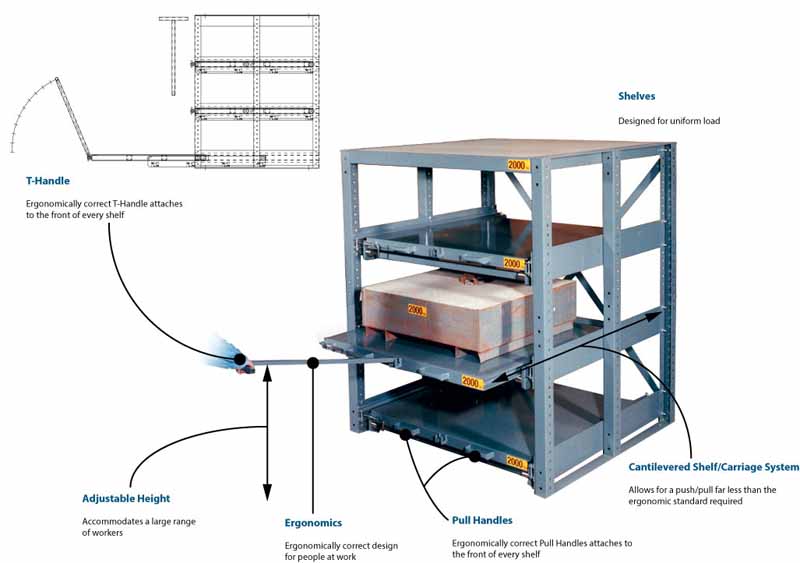

It takes a unique storage system to appropriately manage tools, dies and molds. The shapes, weights and sizes require specific solutions to keep your investment safe and easily accessible. Enhance efficiency with systems that simplify access and save time. Automated retrieval, glide-out shelves, and modular designs make locating and managing tools effortless, while digital tracking provides real-time visibility into tool location, usage, and maintenance. For high-volume or vertical storage needs, automated lifts and robotic systems eliminate manual handling—optimizing workflow and extending tool life.

Rack Storage Systems

Small footprints of up to 36 inches by 36 inches are possible with the glide out as well as crank storage shelves. These systems are made of an all welded construction with the standard 10 gauge steel deck. The shelves can extend up to 75% and have a 5,000 lb load capacity. For added accessibility the shelves can be accessed from either the right or the left side. Customized solutions are possible and any size in any increment can be created. For tight areas a glide out solution is the best use your real estate.

Modula Vertical Lift

With Modula Vertical Lift, store, manage and handle high value molds, dies and tooling in a completely safe, high density storage system. A wide variety of sizes and capacities make this an ideal solution for materials of all sizes across industries.

Integrated Stacker Lift System

Instant adjustability is what makes Prostak the choice for operations that has plastic injection mold storage, stamping die storage, inventory, and maintenance repair equipment in different sizes. This integrated stacker lift system can handle heavier bulkier items while giving you the adjustability you need to make your space work for you. It is easy to operate, provides maximum cube utilization, and can increase your productivity – all a the touch of a button.

From This...

To This...

Optimize Your Operation

TrackingSystemsIoT solutions are the focal point for managing your organization's assets, personnel, and processes. This is enabled by turnkey tracking and sensor systems that capture data, offering a deep insight into your business's performance and the predictive analytics required for optimized management.